BLOG

Comprehensive Guide to Barge Shipbuilding: Shipyards, Boatyards, and Shipbuilders

Peida Machinery Group Co., Ltd. is located in China’s Yangtze golden waterway, the Yangtze River region, which is a shipyard firm of design, construction, and trade, producing bulk shipping, container ships, passenger ships, oil tankers, chemicals ships, tugs, fiberglass boats as well as various engineering ships. Additionally, they run second-hand ships and have been approved by the Classification Societies by meeting all kinds of needs of clients. We sincerely welcome friends all over the world to us!

Introduction to Barge Shipbuilding

Barge shipbuilding is a specialized field within the maritime industry that focuses on the design, construction, and maintenance of barges. Barges are flat-bottomed vessels primarily used for transporting bulk goods, containers, and heavy equipment on rivers, canals, and coastal waters. This article explores the various aspects of barge shipbuilding, including the role of shipyards, boatyards, and shipbuilders.

What is Barge Shipbuilding?

Barge shipbuilding involves constructing robust, efficient, and reliable vessels to facilitate the transportation of goods and materials across waterways. Barges come in various types, such as dry cargo barges, tank barges, and deck barges, each serving different purposes in the maritime industry.

The Role of Shipyards in Barge Shipbuilding

Shipyards are the primary locations where barges are built, repaired, and maintained. These facilities are equipped with advanced machinery, skilled labor, and the necessary infrastructure to handle the complex process of ship construction.

Functions of Shipyards

- Design and Engineering: Shipyards work closely with maritime architects and engineers to design barge vessels that meet specific requirements, including load capacity, stability, and safety standards.

- Construction: Utilizing high-strength steel and advanced welding techniques, shipyards construct the hulls and superstructures of barges. This includes the installation of engines, propulsion systems, and other essential components.

- Quality Control: Shipyards adhere to stringent quality control measures to ensure that the vessels meet international standards and classification society requirements.

- Maintenance and Repair: Shipyards also provide maintenance and repair services to extend the lifespan of barges and ensure their operational efficiency.

The Role of Boatyards in Barge Shipbuilding

Boatyards, although smaller than shipyards, play a significant role in the construction and maintenance of smaller barge vessels and support boats. They often focus on more specialized and custom projects.

Functions of Boatyards

- Customization: Boatyards are known for their ability to customize vessels to meet unique client specifications. This can include modifications to existing barges or the construction of bespoke designs.

- Refitting and Upgrading: Boatyards provide services such as refitting and upgrading older vessels with modern technology and equipment, enhancing their performance and compliance with current regulations.

- Smaller Scale Construction: Boatyards often handle the construction of smaller barges and auxiliary vessels, providing flexibility and specialized services not always available at larger shipyards.

The Role of Shipbuilders in Barge Shipbuilding

Shipbuilders are the skilled professionals and companies responsible for bringing the designs of maritime architects to life. They encompass a range of trades, including welders, engineers, electricians, and carpenters, working collaboratively to construct barge vessels.

Functions of Shipbuilders

- Fabrication: Shipbuilders are involved in the fabrication of individual components and the assembly of the entire vessel. This includes welding steel plates, installing machinery, and fitting out the interior spaces.

- Project Management: Shipbuilders manage the construction process from start to finish, ensuring that the project stays on schedule and within budget.

- Innovation and Technology: Shipbuilders continuously incorporate new technologies and materials into their processes to improve the efficiency, safety, and environmental impact of barge vessels.

Peida Machinery Group Co., Ltd. – Leading the Industry

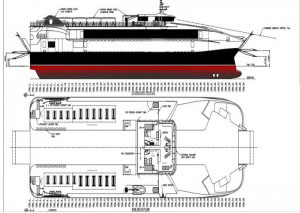

Ro-Ro passenger barge

Peida Machinery Group Co., Ltd., located in China’s Yangtze golden waterway, stands out as a premier shipyard firm specializing in the design, construction, and trade of various vessels. With a focus on producing bulk shipping, container ships, passenger ships, oil tankers, chemical ships, tugs, fiberglass boats, and engineering ships, Peida Machinery Group has established itself as a key player in the maritime industry.

Why Choose Peida Machinery Group?

- Diverse Product Range: From bulk shipping to engineering ships, Peida offers a wide array of vessels tailored to meet the diverse needs of the global maritime market.

- Quality Assurance: Approved by Classification Societies, Peida ensures that all vessels meet international standards for safety, quality, and performance.

- Global Reach: With a strong presence in the international market, Peida Machinery Group serves clients from over 200 countries, demonstrating its global impact and reliability.

- Advanced Infrastructure: Located in the strategic Yangtze River region, Peida’s shipyard is equipped with cutting-edge machinery and technology, enabling efficient and high-quality shipbuilding processes.

Key Benefits of Modern Barge Shipbuilding

1. Efficiency and Cost-Effectiveness

Modern barge shipbuilding techniques have significantly improved the efficiency and cost-effectiveness of constructing and maintaining barges. Advanced materials and automation reduce labor costs and enhance production speed.

2. Environmental Sustainability

Innovations in barge shipbuilding focus on minimizing environmental impact. This includes the use of eco-friendly materials, energy-efficient propulsion systems, and adherence to strict environmental regulations.

3. Safety and Reliability

Stringent quality control measures and adherence to international standards ensure that modern barges are safe, reliable, and capable of withstanding harsh marine conditions.

4. Customization and Versatility

Modern shipbuilding techniques allow for greater customization and versatility, enabling the construction of barges tailored to specific needs and applications. This includes specialized designs for various cargo types and operational environments.

Future Trends in Barge Shipbuilding

1. Automation and Robotics

The integration of automation and robotics in shipbuilding is expected to revolutionize the industry, increasing efficiency and reducing human error in the construction process.

2. Advanced Materials

The development of advanced materials, such as lightweight composites and high-strength alloys, will enhance the performance and durability of barge vessels.

3. Green Technology

The adoption of green technology, including hybrid and electric propulsion systems, will reduce the environmental footprint of barge vessels, promoting sustainability in the maritime industry.

4. Digitalization and Smart Ships

The digitalization of shipbuilding processes and the development of smart ships equipped with advanced monitoring and control systems will improve operational efficiency and safety.

Table: Comparison of Popular Barge Types

| Barge Type | Description | Key Features | Typical Use |

|---|---|---|---|

| Dry Cargo Barge | Used for transporting bulk goods such as coal, grain, etc. | Large storage capacity, open deck | Inland waterways, coastal transport |

| Tank Barge | Designed for carrying liquids like oil, chemicals, etc. | Segmented tanks, safety features | Oil and chemical transport |

| Deck Barge | Flat deck for carrying heavy equipment and vehicles | High load capacity, reinforced structure | Construction, heavy equipment transport |

| Hopper Barge | Used for transporting dredged materials | Hopper doors for unloading | Dredging and material transport |

| Crane Barge | Equipped with cranes for loading/unloading cargo | Onboard cranes, stable platform | Port operations, construction |

Frequently Asked Questions

1. What factors should I consider when choosing a barge shipbuilder?

When choosing a barge shipbuilder, consider their experience, reputation, compliance with international standards, quality of materials and craftsmanship, and their ability to customize vessels to meet your specific needs.

2. How long does it typically take to build a barge?

The construction time for a barge varies depending on its size, complexity, and the shipbuilder’s schedule. On average, it can take anywhere from a few months to over a year to complete a barge.

3. What are the costs involved in building a barge?

The cost of building a barge depends on factors such as the size and type of the vessel, materials used, labor costs, and additional features or customizations. It’s essential to get a detailed quote from the shipbuilder to understand the total costs involved.

In conclusion, barge shipbuilding is a dynamic and essential aspect of the maritime industry, with shipyards, boatyards, and shipbuilders playing crucial roles in the construction and maintenance of these versatile vessels. Companies like Peida Machinery Group Co., Ltd. exemplify the high standards and innovative approaches driving this field forward. Whether you’re looking to build, buy, or maintain a barge, understanding the intricacies of this industry will help you make informed decisions and achieve optimal results.

BLOG

News

Contact Us

Contact: Peida Machinery Group Co. ,Ltd.

E-mail: info@peidaship.com

Tel: 0086 0556 5248992

Phone: 008618855615637

Add: City Anqing, Anhui Province