BLOG

The 6 Biggest Dry Docks in the World: A Dive into Global Maritime Engineering

Dry docks are an essential component of global shipbuilding and repair. These massive structures allow ships to be maintained and constructed on dry ground, making it possible to inspect, repair, or build vessels of all sizes. As shipbuilding has evolved, so too have dry docks, growing in scale to accommodate the ever-larger ships that sail the world’s oceans. From colossal container ships to oil tankers, dry docks are where these giants are born and maintained.

In this article, we explore the 6 biggest dry docks in the world. These marvels of engineering are located in strategic maritime hubs and play a crucial role in the global shipping industry.

H2: What is a Dry Dock and Why is it Important?

A dry dock is a narrow basin or vessel that can be flooded to allow a ship to be floated in, and then drained to provide access to the ship’s hull for construction, inspection, repair, and maintenance. The sheer size of modern dry docks is a testament to the scale and complexity of global shipbuilding operations.

H3: Key Functions of Dry Docks

- Ship Repair: Ships undergo regular maintenance in dry docks to repair any damage, corrosion, or wear and tear on the hull.

- Ship Construction: New vessels, including some of the largest in the world, are built within dry docks to allow easy access to the entire structure.

- Safety Inspections: Ships require regular inspections for safety and regulatory compliance, and dry docks offer the controlled environment needed for detailed inspections.

H2: The 6 Biggest Dry Docks in the World

H3: 1. Hyundai Heavy Industries Dry Dock (South Korea)

Hyundai Heavy Industries (HHI) operates the world’s largest dry dock at its shipyard in Ulsan, South Korea. This behemoth is responsible for constructing some of the largest container ships and oil tankers ever built.

- Length: 672 meters

- Width: 92 meters

- Key Products: Oil tankers, container vessels, bulk cargo ships, and offshore structures.

- Notable Projects: HHI has constructed numerous ultra-large crude carriers (ULCCs) and liquefied natural gas (LNG) carriers.

H3: 2. CSBC Corporation Dry Dock (Taiwan)

CSBC’s dry dock in Kaohsiung, Taiwan, is among the largest in the world, allowing the construction and repair of massive container ships and oil tankers.

- Length: 640 meters

- Width: 100 meters

- Key Products: Container vessels, bulk carriers, and oil tankers.

- Special Features: The dock is capable of accommodating the latest generation of mega container ships.

H3: 3. Dalian Shipbuilding Industry Dry Dock (China)

Located in China’s Liaoning Province, the Dalian Shipbuilding Industry dry dock is a key player in the Asian shipbuilding market. It serves as a hub for the construction of large oil tankers and LNG carriers.

- Length: 530 meters

- Width: 105 meters

- Key Products: Oil tankers, bulk cargo ships, and floating cranes.

- Notable Achievements: Dalian Shipbuilding has delivered some of the world’s largest oil tankers and engineering vessels.

H3: 4. Samsung Heavy Industries Dry Dock (South Korea)

Another South Korean giant, Samsung Heavy Industries (SHI), operates one of the largest and most advanced dry docks in the world. Located on Geoje Island, SHI’s dry dock has been pivotal in constructing some of the world’s largest vessels.

- Length: 640 meters

- Width: 97.5 meters

- Key Products: Oil tankers, container ships, floating production storage and offloading units (FPSOs), and offshore platforms.

- Notable Projects: The SHI dry dock has been instrumental in building the world’s largest container ships.

H3: 5. Peida Machinery Group Co. Dry Dock (China)

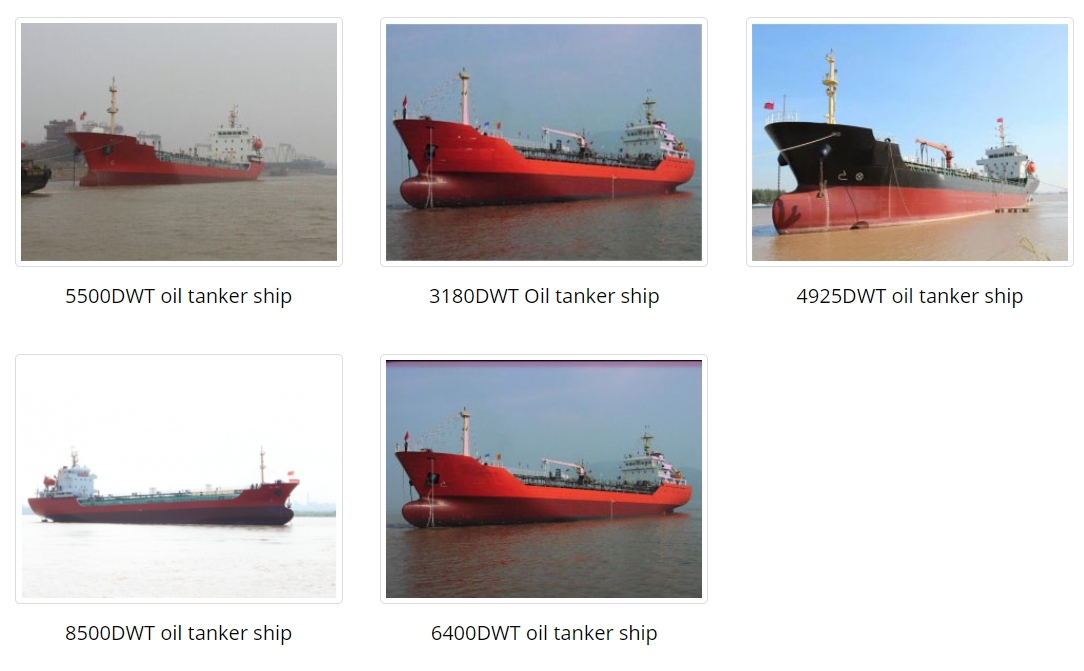

Located along the Yangtze River region in China, Peida Machinery Group Co. operates one of the largest and most versatile dry docks in the world. Specializing in bulk shipping, oil tankers, container vessels, and tugboats, Peida Machinery’s shipyard is a leader in both the construction of new ships and the sale of second-hand vessels.

- Length: 520 meters

- Width: 90 meters

- Key Products: Tugboats, deck cargo barges, oil tanker ships, bulk cargo ships, and passenger ships.

- Unique Offering: Peida also focuses on the construction of fiberglass boats and engineering ships, making it one of the most versatile shipyards globally.

H3: 6. Fincantieri Dry Dock (Italy)

Fincantieri is Italy’s premier shipbuilding company, and its dry dock in Monfalcone is one of the largest in Europe. Fincantieri has a reputation for constructing luxury cruise ships and other large commercial vessels.

- Length: 450 meters

- Width: 84 meters

- Key Products: Cruise ships, naval vessels, container ships, and offshore structures.

- Notable Achievements: Fincantieri has built many of the world’s largest and most luxurious cruise ships.

H2: The Role of Dry Docks in the Global Shipbuilding Industry

Dry docks are essential for the continued expansion and modernization of the global shipping industry. Without these colossal facilities, constructing and maintaining the world’s largest ships would be impossible. The increasing size of ships – from massive oil tankers to ultra-large container vessels – has driven the need for bigger and more advanced dry docks.

H3: Growth in the Oil and Gas Industry

With the global demand for oil and gas remaining high, dry docks are playing a crucial role in constructing and maintaining oil tankers and floating storage units. These vessels are the lifeline of global energy trade, and maintaining their operational efficiency through regular dry docking is critical.

H3: Expansion of the Container Shipping Industry

The growing volume of global trade has led to the construction of mega container ships, many of which are being built in the world’s largest dry docks. These ships can carry tens of thousands of containers and are vital for international commerce.

H3: Construction of Luxury Cruise Ships

Luxury cruise ships have become floating cities, requiring enormous dry docks for construction and maintenance. Companies like Fincantieri and Peida Machinery Group Co. are at the forefront of this industry, building some of the world’s largest and most advanced cruise vessels.

H2: Factors to Consider When Choosing a Shipyard for Dry Dock Services

If you’re in the market for ship repair or construction services, it’s important to choose the right dry dock based on your specific needs. Here are a few key factors to consider:

H3: 1. Size and Capacity

The first and most obvious consideration is whether the dry dock can accommodate the size of your ship. Larger dry docks like those operated by Hyundai Heavy Industries and Peida Machinery Group Co. can handle even the biggest oil tankers and container ships.

H3: 2. Services Offered

Different shipyards specialize in different types of vessels and services. For example, Fincantieri is known for luxury cruise ships, while Samsung Heavy Industries specializes in offshore platforms and floating storage units.

H3: 3. Location

The location of the dry dock is also important. If your ship operates in Asia, it makes sense to use a dry dock located in countries like South Korea or China to minimize transportation costs.

H3: 4. Reputation and Certification

Ensure that the shipyard is certified by relevant maritime authorities and has a reputation for quality. Companies like Peida Machinery Group Co. are approved by multiple classification societies, ensuring they meet international standards.

H2: FAQs about the World’s Biggest Dry Docks

H3: Q1: How does a dry dock work?

A1: A dry dock is a structure that can be flooded to allow a ship to float in and then drained to expose the ship’s hull for repair or maintenance. Once the work is done, the dock is flooded again to allow the ship to sail away.

H3: Q2: What is the largest dry dock in the world?

A2: The largest dry dock in the world is operated by Hyundai Heavy Industries in South Korea, measuring 672 meters in length and 92 meters in width.

H3: Q3: How often do ships need to use a dry dock?

A3: Most ships are required to undergo dry docking at least once every five years for regular maintenance and inspection. However, ships that operate in harsh environments may need to dry dock more frequently.

BLOG

News

Contact Us

Contact: Peida Machinery Group Co. ,Ltd.

E-mail: info@peidaship.com

Tel: 0086 0556 5248992

Phone: 008618855615637

Add: City Anqing, Anhui Province