BLOG

Understanding the Shipbuilding Process Flow: From Design to Launch

Shipbuilding is a complex and fascinating industry that combines engineering, craftsmanship, and innovation. Whether it’s a tugboat, oil tanker, passenger ship, or a bulk cargo vessel, each vessel undergoes a meticulously planned process to ensure it meets safety, efficiency, and performance standards. In this article, we’ll walk through the entire shipbuilding process flow, with insights into the expertise of companies like Peida Machinery Group Co., Ltd.

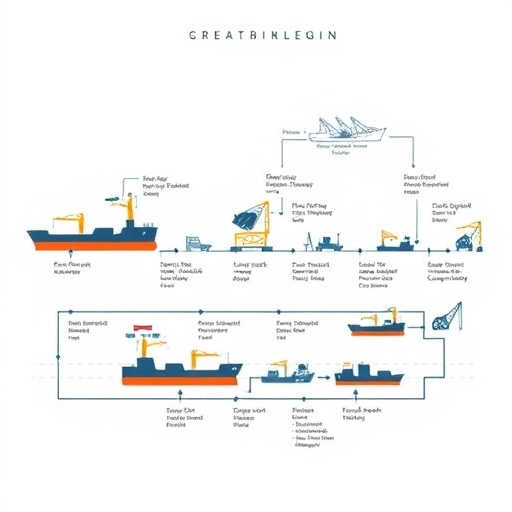

H2: The Shipbuilding Process Flow Explained

H3: 1. Concept Design and Planning

The first stage in the shipbuilding process involves transforming a client’s requirements into a workable ship design.

Key Steps in Design and Planning:

- Client Consultation: Understanding the vessel’s purpose (e.g., cargo transport, passenger ferry).

- Preliminary Design: Sketches and general arrangement plans.

- Feasibility Study: Ensures that the design meets all technical, safety, and regulatory requirements.

H3: 2. Detailed Engineering and Modeling

Once the concept is approved, detailed designs are created using advanced software.

- Structural Design: Plans for hull, decks, and superstructures.

- Systems Design: Includes power systems, navigation equipment, and safety mechanisms.

- 3D Modeling: Helps visualize the entire ship in a virtual environment before construction begins.

H3: 3. Material Procurement

Building a ship requires a wide range of materials and components:

- Steel Plates and Pipes: For hull construction.

- Engines and Propulsion Systems: To power the vessel.

- Electrical Systems: For lighting, communication, and navigation.

H3: 4. Block Construction

Modern shipyards like Peida Machinery Group use modular construction techniques:

- Prefabrication: Large sections of the ship, called blocks, are built separately.

- Assembly: These blocks are then transported and welded together.

Advantages of Modular Construction:

- Time Efficiency

- Cost-Effective

- Precision and Quality Control

H3: 5. Hull Construction and Launching

The hull forms the backbone of any ship. This phase includes:

- Hull Assembly: Welding steel plates to form the main body.

- Installation of Propulsion Systems: Engines, propellers, and rudders.

- Launch Preparation: The ship is moved to the water for the first time using specialized techniques like floating dock launches or slipway launches.

H3: 6. Outfitting

After the ship’s structure is complete, it’s time for outfitting:

- Interior Work: Installation of cabins, galleys, and crew facilities.

- Systems Integration: Setting up navigation systems, engines, and communication tools.

- Safety Equipment: Lifeboats, fire suppression systems, and emergency alarms.

H3: 7. Sea Trials and Delivery

Before a ship is handed over to the client, it undergoes rigorous testing:

- Sea Trials: The vessel is taken out to sea to test its performance under real conditions.

- System Checks: Ensuring all onboard systems function correctly.

- Certification and Handover: Once approved, the ship is delivered to the client.

H2: Types of Ships Built by Peida Machinery Group Co., Ltd.

H3: Tugboat

- Function: Towing or pushing larger vessels.

- Features: High maneuverability, powerful engines.

H3: Deck Cargo Barge

- Function: Transporting heavy cargo.

- Features: Flat deck, large load capacity.

H3: Oil Tanker Ship

- Function: Carrying crude oil or refined petroleum.

- Features: Double hull for safety, advanced pumping systems.

H3: Passenger Ship

- Function: Transporting people across seas and rivers.

- Features: Comfortable seating, safety features for large groups.

Peida Machinery Group’s versatile portfolio includes other vessels like self-dumping barges, container vessels, and floating cranes, meeting diverse client needs.

H2: Advantages of Partnering with Peida Machinery Group

H3: Expertise and Experience

Located in the Yangtze River region, Peida Machinery Group offers comprehensive shipbuilding solutions:

- Design

- Construction

- Trade Services

H3: Approved by Classification Societies

Every ship meets international safety and quality standards, ensuring reliability and performance.

H3: Diverse Product Range

From bulk shipping to specialized vessels, Peida caters to varied marine industries.

H2: Common Challenges in Shipbuilding and Solutions

H3: 1. Material Shortages

Solution: Strategic partnerships with suppliers ensure steady material availability.

H3: 2. Regulatory Compliance

Solution: Collaborating with classification societies to meet all safety and environmental standards.

H3: 3. Delays in Construction

Solution: Modular construction and efficient project management minimize delays.

H2: FAQs About Shipbuilding

H3: 1. How long does it take to build a ship?

The timeline depends on the ship type and size. On average, smaller vessels like tugboats take 12-18 months, while larger vessels like oil tankers can take up to 3 years.

H3: 2. What is the cost of building a ship?

Costs vary depending on the ship’s complexity, materials used, and labor. A small barge may cost a few million dollars, while a large cargo ship could exceed hundreds of millions.

H3: 3. How are ships maintained after delivery?

Regular maintenance includes:

- Hull inspections

- Engine servicing

- System upgrades

Shipyards often provide after-sales services and support.

H2: Comparison of Vessel Types and Their Key Features

| Vessel Type | Primary Use | Key Features |

|---|---|---|

| Tugboat | Towing or pushing vessels | High-power engines, agile navigation |

| Deck Cargo Barge | Transporting heavy goods | Flat deck, high load capacity |

| Oil Tanker Ship | Transporting crude oil | Double hull, advanced safety systems |

| Self-Dumping Barge | Carrying bulk materials | Automated unloading systems |

| Floating Crane | Lifting heavy equipment | High load capacity, versatile use |

| Bulk Cargo Ship | Transporting bulk goods | Large cargo holds, efficient unloading |

| Passenger Ship | Carrying passengers | Comfortable seating, advanced safety |

Final Toughts

The shipbuilding process flow involves multiple stages, each requiring precision and expertise. From concept to sea trials, companies like Peida Machinery Group Co., Ltd. ensure quality at every step. Whether you need a tugboat or a bulk cargo ship, understanding the shipbuilding process is crucial for selecting the right partner.

Let Peida’s advanced shipbuilding solutions guide you to maritime success!

BLOG

News

Contact Us

Contact: Peida Machinery Group Co. ,Ltd.

E-mail: info@peidaship.com

Tel: 0086 0556 5248992

Phone: 008618855615637

Add: City Anqing, Anhui Province